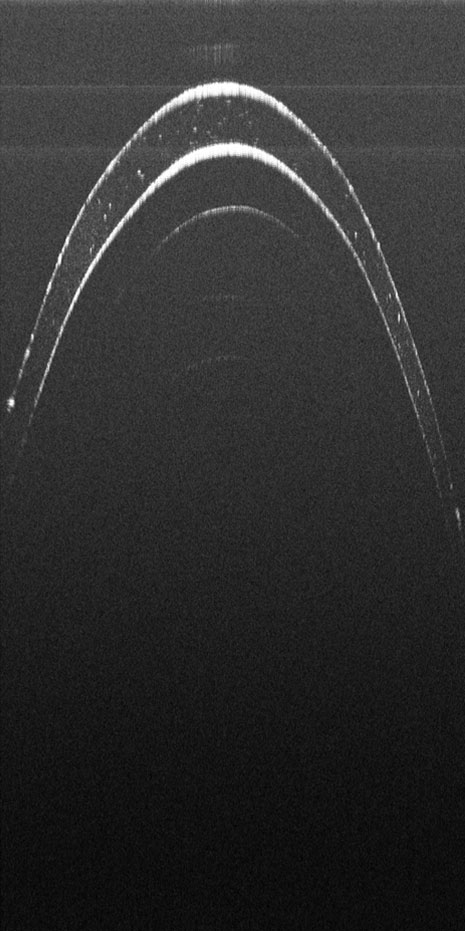

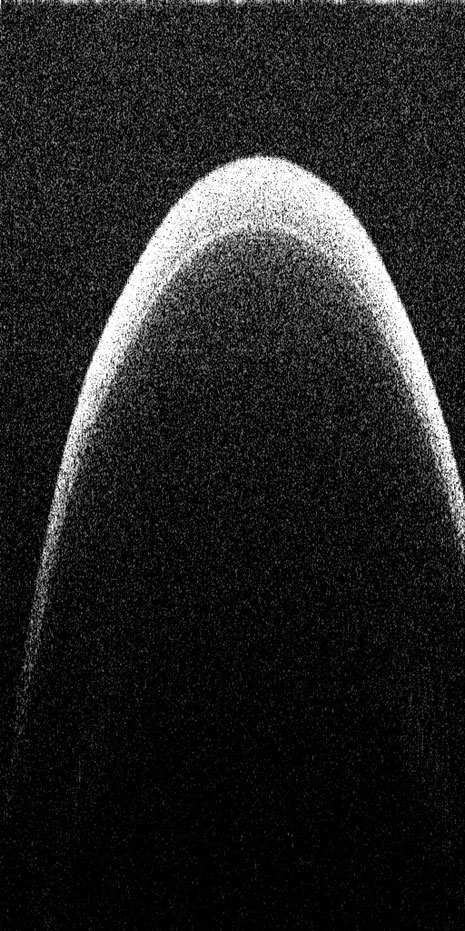

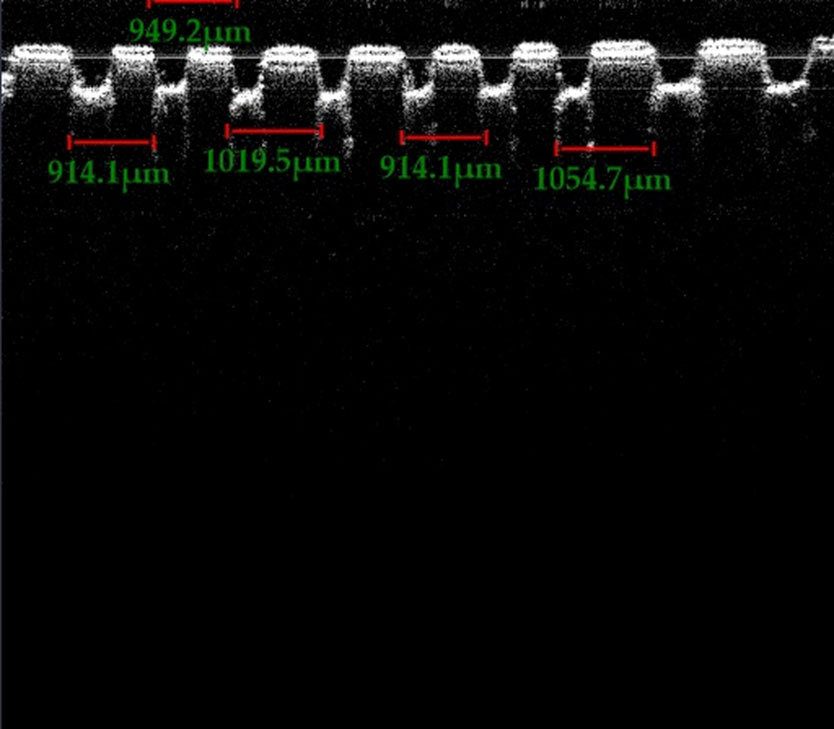

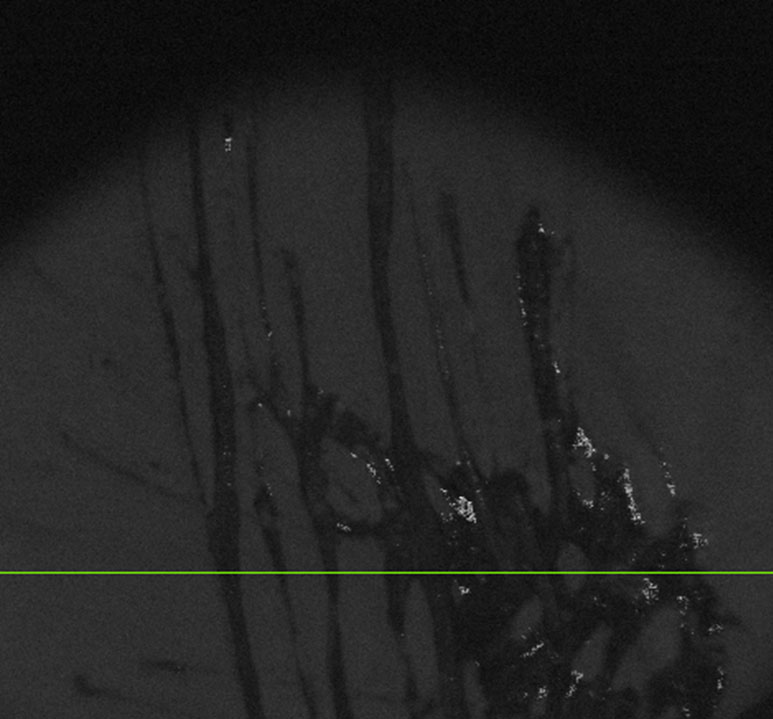

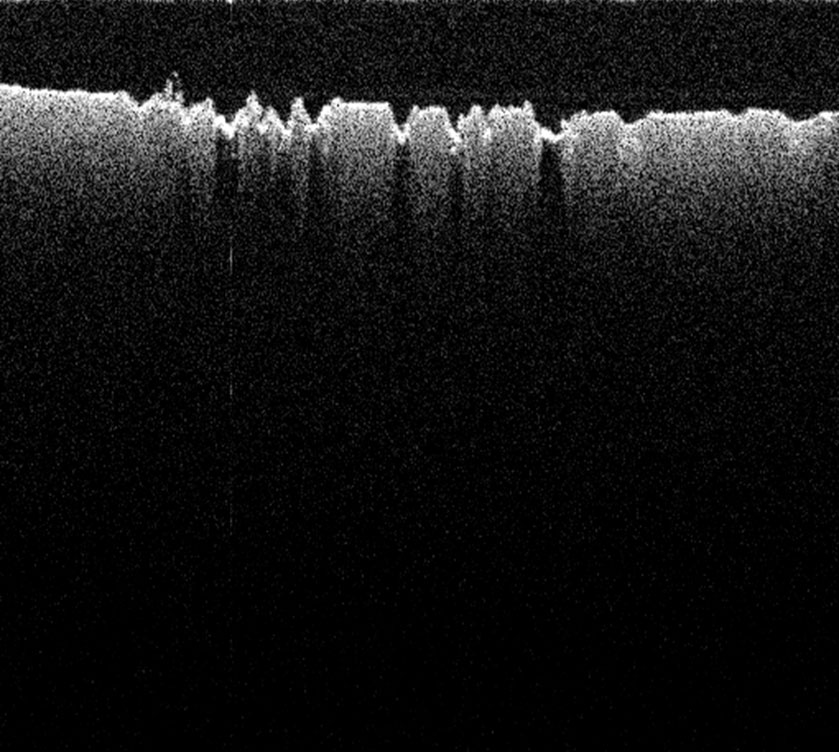

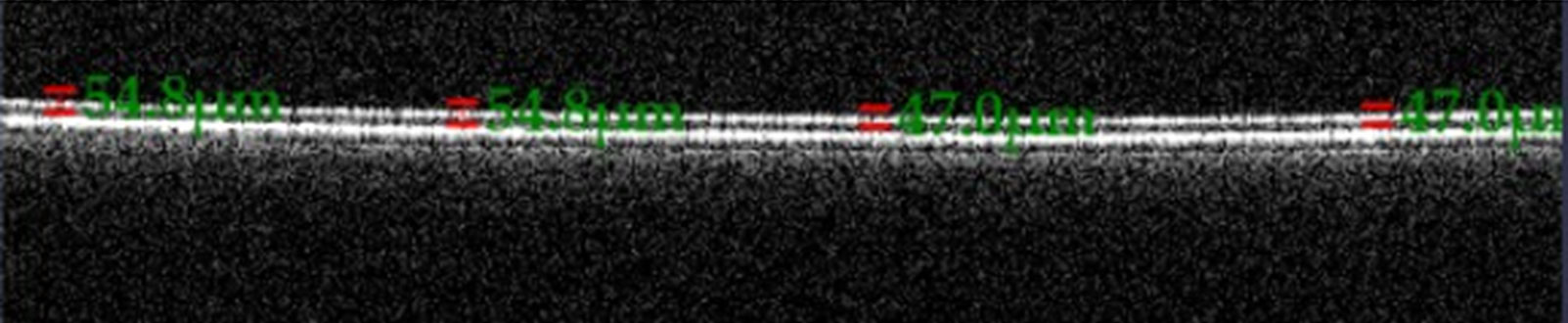

This device harnesses Optical Coherence Tomography (OCT) technology, enabling high-resolution 3D cross-sectional imaging akin to optical ultrasound. Positioned at the forefront of research, it serves diverse domains:

This device, accompanied by off-the-shelf technology, offers customizable specifications, analytical software, cloud storage, and optical/hardware functionalities. Key offerings include:

This device not only serves immediate purposes but also offers potential for further exploration across various sectors. Its adaptable nature, inclusive of customized hardware, software, and comprehensive analytical tools, positions it as a valuable asset in both research and industrial settings.

-on-the-base-plate.jpg)

| AEAR Specification | |

|---|---|

| Wavelength | 840 nm |

| Axial Resolution | 7 µm |

| Acquisition Speed | 13KHz, 40KHz, 80 KHz |

| Diopter Correction | '-16D to +16 D |

| Output power at Sample | <=750 µW |

| Imaging Depth | 2.7 mm |

| SNR | 119dB |

| Scan Options | Line, Area, Circle, Multiline, Long and Radial Scan |

| Tele centricity | 7mm X 7mm |

| Transverse resolution | <=15 µm |

| Retinal FOV | >= 45 |